Capability

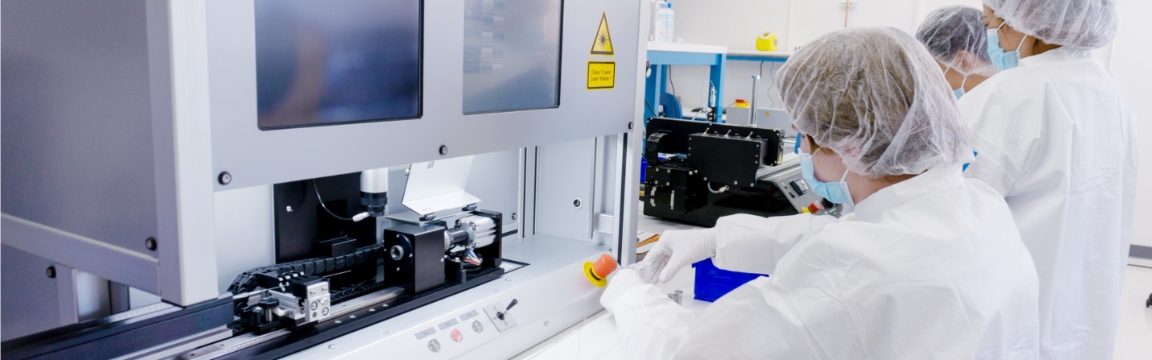

With 20+ years of experience in medical device manufacturing, Second Source Medical provides engineering and quality excellence for clients' success in product development, regulatory approval, time-to-market, and mass production.

Engineering |

Manufacturing |

Quality |

Functional Prototypes Fabrication Design Control (Verification and validation)

|

High Performance/Specialty Components .Microcatheter(1F) .Balloon .Braiding Wire .Hydrophilic Coating .Extrusion .Molded Parts Finished Product Assembly .Lot Build for DVT/Clinical Study .Lot History Record |

FDA-Registered & Audited CM ISO13485:2016 Certified |

Catheter Fabrication Processes

Insert/Over Molding

- Metal, plastics, and catheters can be inserted and molded into a single unit for improved performance and unique attributes.

Hot Die Necking

- The tube is pulled through the heated die and reduced to a defined diameter.

- Precisely repeatable lengths.

Lamination

- Lamination is the process of melting the inner and outer jacket materials together to form a composite catheter shaft.

- Expertise in multi-durometer tubing lamination.

Hydrophilic Coating

- Improve the lubricity and reduce the surface friction to catheter tubing.

- Durable and biocompatible.

Braiding

- Single and multi-durometer options available.

- Different variations of braid density and configurations.

Coil Winding

- Different variations of size, diameter.

- Different materials (stainless steel, nitinol, fiberglass, carbon fiber, nylon, etc.)

RF Tip Forming

- Different tip configurations (conical tip, step tip, bullet tip, soft tip fusion, beverled tip and many more) on a wide range of tubing size and materials.

Hot Air Bonding

- Flexible thermal bonding of catheter tube of dissimilar materials or braided to non-braided section.

- Reflow of outer jacket tubing over braided or non-braided inner tube.

Radiopaque Marker

- Placement and swaging of Au, Pt/Ir, Pt, Ta, Pd radiopaque marker bands.

Catheter Testing

Second Source Medical has a strict quality assurance system to ensure all our catheters meet stringent safety, efficacy, and quality standards according to their intended use and labeling. We offer comprehensive catheter testing services which adhere to ISO standards, ASTM Standards, and FDA guidance documents.

Bending Testing

Tensile Testing

Pushability & Trackability Testing